10 kHz–400 MHz Bulk Current Injection Probe

-

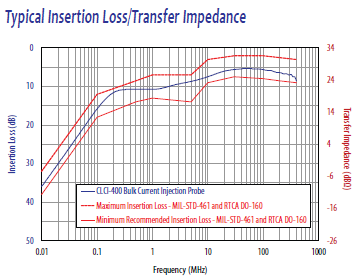

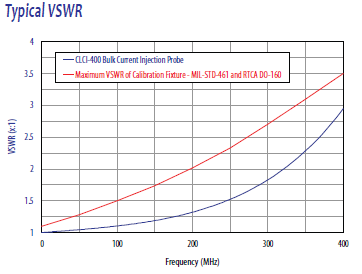

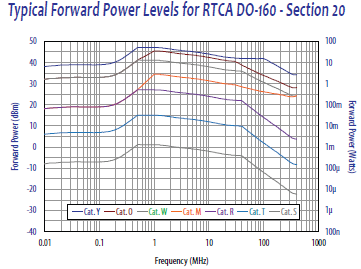

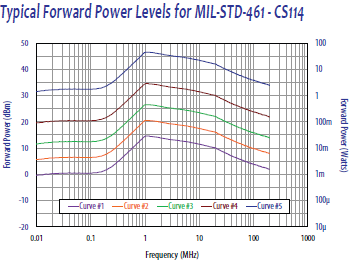

The CLCI-400 is a bulk current injection probe designed for conducted immunity testing in compliance with MIL-STD-461 and RTCA DO-160 standards.

-

It operates across a wide frequency range of 10 kHz to 400 MHz, enabling reliable RF injection for various EMC test requirements.

-

The probe features a 1.575” (40 mm) window diameter, suitable for testing a wide range of cable sizes and bundles.

-

Its 5.75” (146 mm) outer diameter ensures structural stability and durability during lab use.

-

A compact 2.75” (70 mm) width allows for convenient handling and integration into test setups.

-

The probe weighs 4.5 lbs (2.04 kg), offering a solid balance between portability and robustness.

-

It comes equipped with a Type-N (female) input connector for secure and standardized RF connections.

-

Designed to handle up to 100 watts of continuous input power, the CLCI-400 maintains performance across its full frequency range.

-

It is rated for a maximum core temperature of 284º F (140º C), ensuring thermal reliability under demanding test conditions.

-

Available accessories from Com-Power include the FCLC-400 Calibration Fixture, Term-50-100W Power Termination, and ACS-series Power Amplifiers for complete test system integration.

-

Frequency Range: 10 kHz to 400 MHz

-

Complies with MIL-STD-461 and RTCA DO-160

-

Current Injection & Monitoring capability

-

Split-core ferrite design for easy cable insertion

-

Three-year warranty

-

Product: Bulk Current Injection Probe

-

Frequency Range: 10 kHz to 400 MHz

-

Window Diameter: 1.575” (40 mm)

-

Outside Diameter: 5.75” (146 mm)

-

Width: 2.75” (70 mm)

-

Weight: 4.5 lbs (2.04 kg)

-

Input Connector: Type-N (female)

-

Maximum Input Power: 100 Watts (continuous)

-

Maximum Core Temperature: 284º F (140º C)

-

Accessories Available from Com-Power:

-

Term-50-100W Power Termination

1. What problem does the CLCI-400 solve in EMC testing?

The CLCI-400 is used to intentionally inject RF current onto cables to evaluate how susceptible an electronic product is to conducted electromagnetic interference. It helps identify whether external RF disturbances on wiring can disrupt normal operation of the equipment under test (EUT).

2. In what types of test setups is the CLCI-400 most useful?

It is most useful in bulk current injection (BCI) setups where RF energy must be coupled onto complete cables or cable bundles without breaking or modifying the wiring. This is common in military, aerospace, avionics, and high-reliability industrial testing.

3. Which EMC standards typically require or recommend a bulk current injection probe like the CLCI-400?

The CLCI-400 is commonly used in conducted susceptibility tests defined in:

-

MIL-STD-461 (CS114, CS115, CS116)

-

RTCA DO-160 (Section 20)

These standards specifically call for current injection onto interconnecting cables rather than voltage injection at the power port.

4. How is bulk current injection different from conducted immunity testing with CDNs?

Bulk current injection couples RF energy magnetically onto cables using a clamp, while CDNs inject RF electrically through a defined impedance network. BCI is preferred when cables cannot be disconnected, when multiple conductors must be stressed together, or when the standard requires realistic cable coupling rather than controlled port injection.

5. How does the CLCI-400 differ from a LISN?

A LISN is used mainly for emissions measurement and power-line immunity, providing a controlled impedance at the EUT power input. The CLCI-400 does not stabilize impedance or measure noise; instead, it injects RF current onto signal, control, or power cables to simulate external electromagnetic disturbances.

6. How is the CLCI-400 different from a current monitoring probe?

Current monitoring probes are optimized for measurement accuracy and sensitivity, while the CLCI-400 is optimized for power handling and efficient current injection. Although the CLCI-400 can measure current, its primary purpose is stressing cables rather than precision monitoring.

7. When would an engineer choose the CLCI-400 instead of a voltage injection method?

Engineers choose the CLCI-400 when they need to replicate real-world RF coupling onto cables, such as exposure to nearby transmitters, radar, or onboard RF systems—conditions where interference enters via wiring rather than through power terminals.

8. What types of products are typically tested using the CLCI-400?

It is commonly used for testing:

-

Military and defense electronics

-

Avionics and aerospace systems

-

Industrial control equipment

-

Automotive and rail subsystems

-

Medical and mission-critical devices with long cable runs

9. Why is a split-core design important in a bulk current injection probe?

A split-core design allows the probe to be clamped around cables without disconnecting them. This saves setup time, reduces the risk of altering cable behavior, and better represents real-installation conditions required by many standards.

10. How does the CLCI-400 fit into a complete conducted susceptibility test system?

The CLCI-400 is typically used with a signal generator, RF power amplifier, directional coupler or power meter, and a calibration fixture. Together, these components ensure the required current level is injected accurately and repeatably across the test frequency range.

11. Why is calibration critical when using the CLCI-400?

Calibration ensures that the forward RF power delivered to the probe results in the intended current on the cable. Without calibration, test results may not meet standard requirements or be reproducible between labs.

12. Can the CLCI-400 be used for pre-compliance testing?

Yes. Many engineers use it during design validation to identify susceptibility issues early, allowing cable routing, filtering, or shielding improvements before formal compliance testing.

13. How does bulk current injection testing improve product robustness?

By forcing controlled RF currents onto cables, the test reveals weak points in grounding, shielding, filtering, and internal circuit immunity—helping designers harden products against real-world electromagnetic environments.

14. What makes the CLCI-400 suitable for high-severity immunity testing?

Its efficient coupling over a wide frequency range allows required test levels to be achieved without excessive amplifier power, making it practical for stringent military and aerospace immunity categories.

15. Is the CLCI-400 intended for emissions testing?

No. The CLCI-400 is primarily an immunity tool, not an emissions measurement device. While it can monitor current, emissions compliance typically relies on LISNs, antennas, and EMI receivers rather than injection probes.

16. How is the Com-Power FCLC-400 calibration fixture used with the CLCI-400, and why is it important?

The Com-Power FCLC-400 calibration fixture is used to calibrate and verify the current injection levels of the CLCI-400 before performing immunity tests. The fixture creates a controlled, coaxial transmission path that allows the probe to clamp around a centered conductor while maintaining consistent impedance. This setup enables accurate determination of insertion loss and establishes the relationship between forward RF power and induced current. Using the FCLC-400 ensures that the injected current during testing truly matches the levels required by standards such as MIL-STD-461 and RTCA DO-160, making test results repeatable, traceable, and defensible during audits or compliance reviews.