150W Low-Frequency Power Amplifier

30 Hz to 150 kHz operating range with up to 150 W output into low-impedance loads, supporting 1 Ω through 8 Ω operation per minimum output specifications.

Designed for conducted and radiated susceptibility testing, supporting MIL-STD-461 and RTCA DO-160 requirements.

10 kΩ input impedance and nominal 1.4 Ω output impedance enable stable operation with injection transformers and coupling networks.

Forced-air cooling and wide-range AC input (100–250 VAC) with built-in overload, over-temperature, and over-current protection.

Used for CS101 conducted susceptibility testing to inject low-frequency disturbances onto power and signal lines.

Applied in RS101 radiated susceptibility testing for evaluating low-frequency magnetic field immunity.

Ideal for aerospace DO-160 Section 18 testing, where controlled low-frequency excitation is required.

Drives coils, transformers, and custom fixtures reliably in low-frequency EMC immunity test setups.

Digital front-panel monitoring of temperature and output current helps maintain safe operation during extended tests.

3U rack-mount design for EMC laboratories enables easy integration into automated compliance test systems.

Frequency Range: 30 Hz to 300 kHz for low-frequency conducted and radiated immunity testing

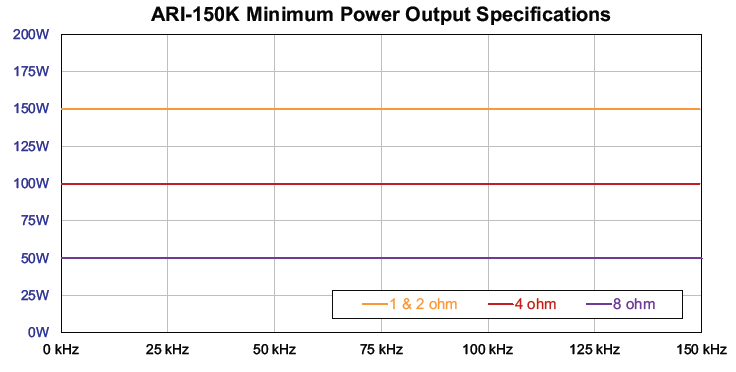

Output Power: Up to 150 W into 1 or 2 Ω loads, 100 W into 4 Ω, and 50 W into 8 Ω with ≤8% distortion

Compliance Support: Designed for MIL-STD-461 (CS101, RS101) and RTCA DO-160 susceptibility testing

Protection Circuitry: Built-in safeguards against over-temperature, over-current, and improper load conditions

Low Distortion Performance: ≤8% total harmonic distortion across the operating frequency range

Stable Phase Response: ±5° phase accuracy up to 75 kHz for repeatable test results

Wide AC Input Range: Operates from 100–250 VAC, 50/60 Hz for global laboratory use

Real-Time Monitoring: Front-panel indicators for amplifier temperature and output current status

Laboratory-Ready Design: Forced-air cooling for continuous operation during extended test cycles

Warranty: Three-year manufacturer warranty for long-term reliability

GENERAL

Product Description: Power Amplifier

Application: Conducted and Radiated Susceptibility Testing

Standards: MIL-STD-461, RTCA DO-160, and related immunity standards

Frequency Range: 30 Hz to 300 kHz

Output Power: Refer to minimum power output specifications graph

Input Impedance: 10 kΩ nominal

Output Impedance: 6.25 mΩ nominal

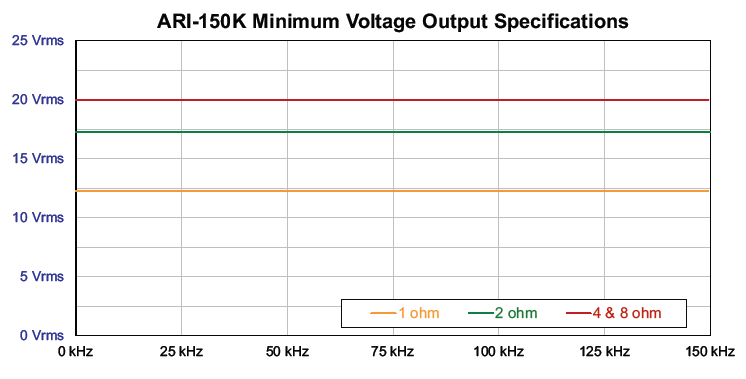

Output Voltage: Refer to minimum voltage output specifications graph

Distortion: ≤8%

DC Drift: < ±1.5 mV after 30 minutes of operation

Phase Response: ±5° up to 75 kHz

ELECTRICAL

AC Input Power: 100–250 VAC, 50/60 Hz

Maximum Power Consumption: 1000 VA

INPUT / OUTPUT CONNECTORS

Input Connector: BNC female

Output Connectors: Two 4 mm banana jack binding posts

AC Input Connector: IEC C13 receptacle

ENVIRONMENTAL

Operating Temperature: 40 °F to 104 °F (5 °C to 40 °C)

Cooling: Forced air

MECHANICAL

Dimensions (H × W × D): 6.125 in × 19 in × 23.25 in (15.9 cm × 48.3 cm × 59 cm)

Rack Mount Dimensions: 3U, 5.25 in × 19 in × 22.25 in (13.34 cm × 48.3 cm × 56.5 cm)

-

What injection method is this amplifier typically used with (CS101 / DO-160 Sec 18)?

Most setups drive an injection transformer (or a coupling transformer) to place the disturbance voltage/current onto the EUT power leads while the EUT is powered through the appropriate LISN/coupling network. -

How do I choose the right output load configuration (1 Ω / 2 Ω / 4 Ω / 8 Ω) for my setup?

Choose based on the effective impedance of the injection device + cabling + coupling network seen by the amplifier; verify by measuring output current and voltage at the amplifier terminals under test conditions. -

How do I prevent amplifier shutdown or clipping when sweeping 30 Hz–300 kHz?

Keep the sweep within the minimum output capability curve, use stepwise level increases, and monitor output current / temperature; if current rises sharply at certain frequencies, it usually indicates fixture resonance or too-low effective impedance. -

Where should I measure level—at the amplifier output or at the EUT input?

For susceptibility testing, level control is typically based on what reaches the EUT line (via a monitor port/coupler, current probe, or measured line voltage), not just the amplifier terminals, because the injection network can add frequency-dependent loss. -

What signal source level is needed to drive the amplifier correctly?

Use a signal generator with enough headroom to achieve required output without overdriving; keep the generator within its low-distortion range and increase power using the amplifier rather than “hot” source levels. -

Can I use this amplifier to drive an RS101 loop/coil fixture for magnetic field susceptibility?

Yes—this type of low-frequency power amp is commonly used to drive field coils/loops, but you must confirm the coil’s impedance vs frequency and watch for resonances that can force excessive current. -

What output protection practices should I use with transformers and coils?

Use short, heavy-gauge leads, avoid open/short transitions while energized, and consider adding current limiting in the test plan (and, when appropriate, protective components in the fixture) to prevent abrupt load changes. -

How do I handle grounding and noise to avoid corrupting measurements at low frequencies?

Use a single-point ground strategy, keep high-current return paths short, separate measurement cabling from power cabling, and avoid ground loops between the amplifier, injection network, and measurement instruments. -

What instruments are typically paired with this amplifier for closed-loop leveling?

A typical chain includes a signal generator, power meter or RMS voltmeter, and/or a current probe with measurement receiver/scope, plus any directional coupler/monitor port provided by the injection network. -

What’s the practical impact of ≤8% distortion and phase response for susceptibility work?

In immunity tests, the goal is controlled stress on the EUT; distortion mainly affects waveform purity, so you ensure compliance by meeting the required test level at the EUT and keeping operation out of severe clipping where harmonics can create unintended excitation paths. -

What other Com-Power products are commonly paired with this amplifier for better control and measurement during susceptibility tests?

In addition to the amplifier, engineers often pair it with Com-Power power meters or RMS voltmeters (e.g., PMX or RMS series) to measure and verify actual output levels delivered to the injection network or EUT. These measurement instruments help ensure the amplifier’s output stays within test limits, especially when using coupling networks or coils whose impedance varies with frequency. Using real-time level verification improves repeatability and compliance confidence in CS101 / RS101 and RTCA DO-160 immunity tests. -

What other Com-Power products complement this amplifier for broader EMC testing and how are they used?Injection Transformers / Coupling Networks: Com-Power coupling devices such as CFT- and CN- series networks are used to inject disturbance voltages or currents into the device under test (DUT) lines when connected with this amplifier. They define the injection point and impedance environment for CS101/RS101 tests.Field Coils & Loop Fixtures: For magnetic field susceptibility (RS101 / DO-160 Sec 18), Com-Power field coils and magnetic loop fixtures convert amplifier output into a defined field at the DUT location.Power Line Impedance Stabilization Networks (LISNs): While this amplifier doesn’t directly use LISNs for output, LISNs are essential for conducted emission paths when measuring with receivers/EMI analyzers in adjacent tests or when using coupled setups.

Other EMC Test Equipment

- Absorbing Clamps

- Antenna Kits

- Antenna Masts - Automated and Manual

- Antennas

- Bulk Current Injection probes

- CDNs - Coupling Decoupling Network

- Comb Generators

- Conducted Immunity Test Systems

- Current Monitor Probes

- Current Probe Calibration Fixtures

- EM Clamps

- Feed Through Capacitor

- ISNs - Impedance Stabilization Network

- Line Impedance Stabilization Networks

- Magnetic Field Generator

- Near Field Probes

- Power Amplifiers

- Pre-compliance Emissions Test Systems

- Preamplifiers

- Spectrum Analyzers

- Surge Generators

- System Controllers

- Transient Limiters

- Tripods For EMC

- Turntables